Our Services

Troubleshooting Electric Submersible Pumps

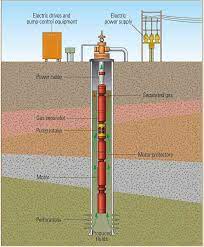

Herein the company would like to focus on the artificial lift technical support that can be provided concentrating on the main two methods of ESP electric submersible pump.

Electric submersible systems use multiple pump stages mounted in series within a housing, mated closely to a submersible electric motor on the end of the tubing and connected to surface controls and electric power by an armor-protected cable.

SRTP Pipelines for High Paraffin Oil Flow Lines

Herein the company would like to focus on the artificial lift technical support that can be provided concentrating on the main two methods of ESP electric submersible pump.

Polymers Designed for Application Nylon/PPS/PVDF

Lightweight, Low-Cost Creative Solutions

Half Sizes

Many Pressure Ratings 275, 500, 750, 1,000, 1,200, 1,500 etc. PSI

Rapid Low-Cost Installation

Service Model to Make Planning and Installation Easy No Derating of Product

Pipeline Construction, wrapping, welding testing

- Construction, welding, fabrication.

- Hydro test and NDT.

- Vessels and shipping pump installation.

- Sandblasting and Painting.

- Inspection and examination

- Pressure testing and Hydro test

- Cleaning and flushing

Maintenance of Sucker Rod .

A sucker rod is a steel rod, typically between 25 and 30 feet (7 to 9 meters) in length, and threaded at both ends, used in the oil industry to join together the surface and downhole components of a reciprocating piston pump installed in an oil well. The pumpjack is the visible above-ground drive for the well pump, and is connected to the downhole pump at the bottom of the well by a series of interconnected sucker rods. Sucker rods are also commonly available made of fiberglass in 37 1/2 foot lengths and diameters of 3/4, 7/8, 1, and 1 1/4 inch. These are terminated in metallic threaded ends, female at one end and male at the other. The surface unit transfers energy for pumping the well from the prime-mover to the sucker rod string. In doing this, it must change the rotary motion of the prime-mover to reciprocating motion for the sucker rod. And it must reduce the speed of the prime-mover to a suitable pumping speed. Speed reduction is accomplished by using a gear reducer, and rotary motion of the crank shaft is converted to oscillatory motion by means of a walking beam. The crank arm is connected to the walking beam by means of a pitman arm. The walking beam is supported by a Samson post and saddle bearing. The horse head and bridle are used to ensure that the pull on the sucker rod string is vertical all times so that no bearing movement is applied to that part of sucker rod string above stuffing box. The polished rod and stuffing box combination is used to maintain a good liquid seal at the surface

Hydraulic Test Services:

We are equipped with fully automated controlled and Isolated fixed test units up to 15,000 PSI and portable test units up to 20,000 PSI,

in which we can test the integrity of commencements and assure no leakage. The tests are managed and performed by qualified and

competent engineers according to API standards leakage.

Wellhead installation and maintenance :

- Performing routine maintenance on wellhead and determining when and what kind of maintenance needed.

- Wellhead integrity test.

- On line wellhead troubleshooting (casing heads, casing spools, tubing heads, etc.)

- Integrated spare parts services.

- Installation and Retrieval of non return valves, and VR plugs on wells.

- Lubricator assembly for BPV and VR plug.

- Monitoring well pressure, monitoring for annulus pressures, checking for missing items on well heads and arrange for replacement.

Valves and X-Mas tree installation and maintenance

- Inspect, troubleshoot and repack any size FMC, WG, solid block, CIW, plug valve, gate valve, and actuators.

- Routine / Non Routine Valve Maintenance.

- Emergency valve sealing using a valve special field kit.

- Valves and actuator commission and start up.

- Conduct in the field install and testing on valves.

- Greasing and flushing all valve types.

- Performing job safety analysis (JSA) to identify possible safety concerns.

- Carrying out an integrity leak on X-mas tree valves.

- Documentation of repair / testing / assembly activities.

- Implementation and gathering all data of the valves at the field, with TAG No plates.

- Assembly, maintain and test ESD valves.

- Assembly, maintain and test ESD valves.

Artificial Lift (ESP) Services:

Future Petroleum Services is a private limited Egypt based company with unrivalled ESP expertise and strong locally presence in Egypt fields.

The company was established with primary objective of supporting and improving artificial lift performance for operators through out the ESP field in Egypt, with significant emphasis on electric submersible pumps (ESPs).

ALS provides unparalleled and unbiased technical expertise through its team of consultants having worked with numerous operators in more than 12 companies in Egypt, and in a wide variety of environments and situations, ALS brings a unique level of experience to the benefit of existing and future clients.

While ESP failures are typically costly, most are avoidable, Future petroleum services provides unbiased third party technical support, skills and expertise to improve performance, increase equipment run lives, and reduce cost.

ALS department with our company performs a broad range of services with a specific emphasis on technical support, including (but not limited to):

1- Application engineering and well designs.

2- ESP manufacturing and supply Centre audits with full quality inspection services.

3- Dismantle inspection failure analysis (DIFA) plus Root cause analysis (RCA).

4- Load flow analysis and field operation support with highly professional experienced engineers.

5- ESP Cable test, inspect and repair with highly accurate evaluation for reusing again and save thousands of USD.

6- Remote operational monitoring and well surveillance.

7- Commercial package preparation plus Bid/Tender preparation and evaluation.

8- Optimization of all forms of artificial lift. 9- Provide bespoke training courses and onsite field training for your company personals.

HSE POLICY:

- Safety Management

- Advanced Health and Safety

- Safety Management System

- Risk Assessment and Risk Management

- Accident / incident reporting procedures, accident investigations and analysis

- Accidents Prevention and Loss Control

- Permits to Work System.

- Safety, Health, and Environmental Auditing

- Safety and Health Training

- Emergency preparedness procedures

- Machine safeguarding

- Permit to Work system

- Emergency preparedness procedures. Incident Investigation

- SAFETY PRINCIPLES AND RISK MANAGEMENT

- LEGISLATION

- HAZARD RECOGNITION AND CONTROL

- EMERGENCY PREPAREDNESS AND FIRE PREVENTION

- Industrial Hygiene

- ERGONOMICS

- WORKPLACE INSPECTION AND ACCIDENT INVESTIGATION

- PROGRAM DEVELOPMENT AND IMPLEMENTATION

- Process Hazard Analysis (PHA)

- Leadership

- Personal protective equipment

- Fire safety

- Hazard communication